Are you thinking about dabbling in homebrew or do you know someone who wants to learn? A 1 Gallon Homebrew Starter Kit is a great place to start. Brewing beer is easy! Just follow our instructions below and you will see how easy it really is.

Equipment & Ingredients You Will Need:

- 2 Gallon Stock Pot (or larger)

- 1 Gallon Clear Glass Jug

- Plastic Airlock

- Rubber 6.5 Bung

- Mini Auto-Siphon and at least 4 feet of tubing

- 2 Gallon Plastic Fermenting Bucket and Grommeted Lid

- Large Muslin Grain Bag (or small coarse nylon grain bag)

- 1 oz Priming Sugar

- One Step Cleaner

- Floating Thermometer

- 3/8" Bottle Filler

- 8 - 10 beer bottles (or a full case good for several brews)

- Bottle Caps

- Capper

- Ice used at the end of your boil

- 1 Gallon Recipe Kit

Note: Much of the equipment & ingredients listed above are included in our 1 gallon equipment starter kits. The bottles, capper, and stock pot are not included in the 1 gallon starter kits.

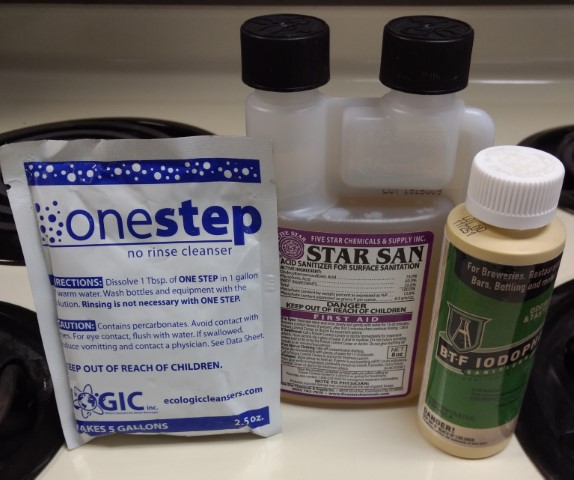

Clean & Sanitize: Using cleaners and sanitizers such as Star San, Iodophor, or One Step to thoroughly clean & sanitize all of your equipment is very important. Any equipment such as your buckets, lids, airlocks, siphons, spoons, jugs, stoppers, & any other equipment that touches your beer should be thoroughly cleaned & sanitized at every step in the beer making process.

Steeping The Grain: Heat up about 1.5 gallons of water in a stock pot. Turn off the heating source once the water reaches 155°F. Don’t worry if you are a few degrees warmer or cooler than 155°F. Just be sure that the water doesn’t exceed 168°F. Put your grain in the steeping bag and soak the grains. After at least 45 minutes, lift the grain out of the hot water and pour 4 cups of warm water through the grains while collecting the runoff back into the pot. The purpose of rinsing the grain is to collect as much sugar and flavor from the grains that remain trapped inside the grain bag. Now you can discard the grain.

Note: we used a stainless steel strainer to rest our grains on top of the stock pot. This is helpful but not necessary.

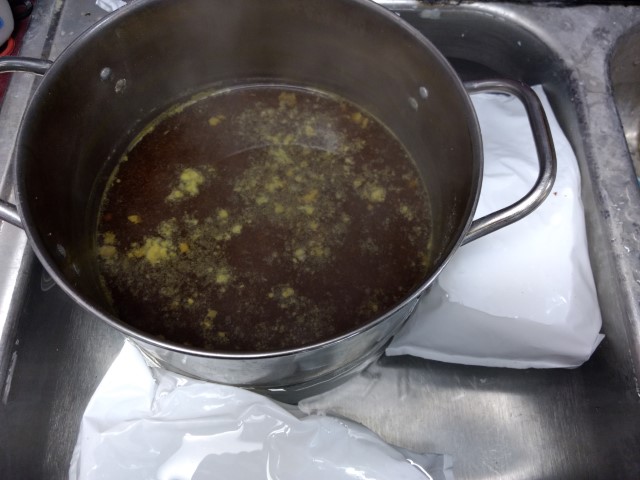

The Boil: Bring the sugary liquid (also known as “wort”) to a boil. Occasionally stir the wort to prevent the wort from boiling over. Once the wort is boiling, you can now add hops according to the recipe hop schedule. The first hops added to the wort are generally used for bittering. Hops added with 10-30 minutes left in the boil are flavoring hops. Hops added with 5 minutes or less remaining in the boil are used for aroma.

Chilling: After the boil, you will need to quickly chill your wort to below 80°F. Fill your sink with enough ice water so that you can place the stock pot in the ice water bath. Make sure you don’t put too much ice water in the sink or the water will spill over into your pot and contaminate your beer. Once the wort reaches 80°F or lower, you can now pour the wort into your sanitized bucket. You want to have the bucket filled to half way up the 2 gallon bucket. You can top off the wort with clean water if you don’t quite have 1 gallon of beer in the bucket.

Note: We used ice packs instead of ice cubes in the picture above. Ice cubes will work better, but we just had a bunch of ice packs on hand and decided to use these for the chilling process.

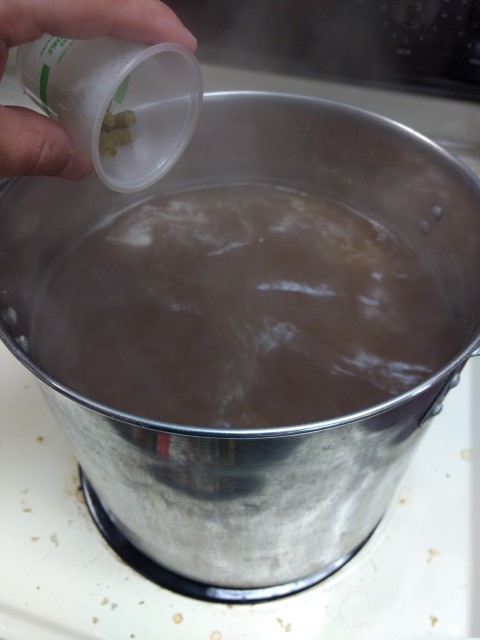

Pitching the Yeast: If you have dry yeast, cut open the yeast packet with sanitized scissors and sprinkle the yeast on top of the wort. Seal the bucket with the grommeted lid. Fill the 3 piece airlock half way up with clean water and insert into the lid’s grommet.

Note: If you have a hydrometer, make sure to take a hydrometer reading before you pitch your yeast. This will provide you with your Starting Gravity and will allow you to know the exact alcohol content of your beer. Click here for instructions on how to use & read a hydrometer. While using a hydrometer isn't necessary to brew and ferment delicious beer, we highly recommend using a hydrometer to accurately calculate your alcohol and to help determine when your beer is done fermenting. For help reading a hydrometer, please see our How To Read A Hydrometer instructions.

Fermentation: Over the next few days, the wort will begin to ferment aggressively. You will see the airlock bubbling rapidly. The rate of bubbling will begin to slow down after 3-4 days as the yeast eats the sugar and creates alcohol. After 5-7 days, remove the lid and transfer the beer to the glass carboy. Make sure to leave behind as much of the yeast that has accumulated at the bottom of the bucket as you can. Place the bung on top of the jug and insert the airlock making sure you fill the airlock half way with clean water.

Bottling: After 5-7 days in the jug, there shouldn’t be anymore bubbling in the airlock. Now you are ready to bottle. Pour a half a cup of clean water into a sauce pan and mix in the priming sugar. Heat up the sugary mixture until it boils. Then pour the liquid into your fermenting bucket. Transfer your beer from the jug to the fermenting bucket using your auto-siphon and tubing. This will help ensure that the sugary mixture thoroughly mixes with the beer. Now you are ready to transfer the beer to the bottles. We recommend attaching the bottle filler to the end of the siphon tubing to avoid making messes and wasting your beer. Fill each beer bottle until the beer reaches the very top of the bottle and then remove the bottle filler. There will be about an inch of empty space at the top of the bottle once the bottle filler is removed. Do not top off this empty space. Once all the beer bottles are full, you will cap each bottle using a bottle capper. Alternatively, you can use EZ cap flip top bottles if you don’t have a capper and caps. Leave the bottles at room temperature and the beer will carbonate within 7-10 days. Refrigerate the beer only after it has been allowed to carbonate.

Enjoy!